Formosa Srt Plate Hull Construction

All Formosa built hulls are designed to stretch the limits of offshore boating but are equally at home used as a skiing boat in a lake with the family or fishing in an estuary.

The Formosa SRT™ Plate Hull is built to the same engineering standards employing true plate boat building techniques. Longitudinal and lateral structures are welded to the planing hull to lock structure and outer side sheets together providing a strong and stable platform.

Formosa boats are built from the best corrosion resistant marine grade Aluminium. They are built tough with the ultimate subfloor structure and a minimum of 4mm side and bottom sheets. 5mm bottom sheets are standard on the larger models 635 and up, with the ability to upgrade sheet thickness if desired on models 495 to 595. Be wary of boats masquerading as plate boats simply because they have flat side sheets with a lack of pressings. These ‘pretend’ plate boats are most likely using aluminium sheet less than 4mm in thickness and are a completely different build to a Formosa.

The Formosa Weld

Formosa Marine use the world’s Best Pulse Mig Welding Machines which are capable of laying down a beautiful looking and an extremely strong weld. Quality welding machines ensure quality welds and Formosa Marine leave our welds very visible – the welds are not sanded back for looks. Owners can see how the boats are welded together which shows the strength and quality. It’s a feature Formosa are proud of.

Size does matter

Up to July 2020, Formosa Marine measured their boats by hull length, from the transom to the nose, and didn’t include the Bowroller or other accessories on the boat. Other manufacturers measure and market their boats larger which may include the bowsprit and /or fittings.

Formosa Boat Sizes are now more comparable to others on the market. So the boat measurements now include the Formosa’s Heavy-duty Bowroller and the Boat Graphics mirror this change.

If you see a Formosa 595 boat next to another manufacturer’s 615 for example, at your next boat show, your eyes are not deceiving you, yes the 615 looks like it would fit inside our 595 hulls.

Formosa Safety and Stability

All Formosa built hulls are designed to stretch the limits of offshore boating but are equally at home used as a skiing boat in a lake with the family or fishing in an estuary.

The Formosa SRT™ Plate Hull is built to the same engineering standards employing true plate boat building techniques. Longitudinal and lateral structures are welded to the planing hull to lock structure and outer side sheets together providing a strong and stable platform.

Formosa boats are built from the best corrosion resistant marine grade Aluminium. They are built tough with the ultimate subfloor structure and a minimum of 4mm side and bottom sheets. 5mm bottom sheets are standard on the larger models 635 and up, with the ability to upgrade sheet thickness if desired on models 495 to 595. Be wary of boats masquerading as plate boats simply because they have flat side sheets with a lack of pressings. These ‘pretend’ plate boats are most likely using aluminium sheet less than 4mm in thickness and are a completely different build to a Formosa.

High Sides and Wide Beam

Safety and boat performance while out on the water has always taken precedence in the Formosa Hull design. Famous for their high sides and wide beam, you’ll get with a Formosa the extra protection and more comfort of a user-friendly, large interior space and the extra stability on the water.

Don’t be fooled by performance ‘cowboys’ in their ‘skinny’ boats. A Formosa built boat is capable of going anywhere and in various weather conditions as other boats of like and are even more capable when at your favourite fishing spot. In a Formosa boat, your day out will be more enjoyable with the family or with fishing buddies, giving you heaps of room to move around and even utilising the transom, extending the boat’s interior with the ‘Active Transom’ design.

Other Manufacturers, with a sharper deadrise, boast an ability to cut through seas better than others but then try to hide the fact that their boats are so narrow. Their sharper deadrise may reduce time getting to your favourite fishing location by a few minutes, but compromise your entire day out with your mates by having little internal deck space and less stability. The result is spending an uncomfortable day out rubbing shoulders with your mates and apologising to each other for getting in the way.

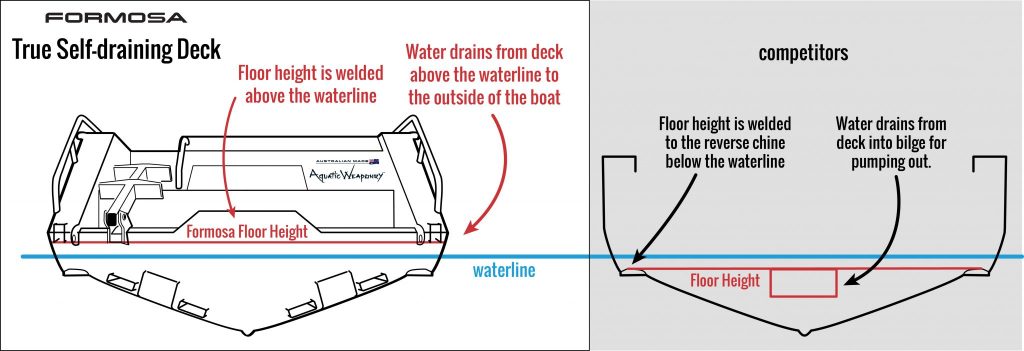

True Self-draining Deck

The Formosa hull design allows the boats to have a high floor which is situated above the chine line, or waterline, giving you what Formosa calls a “true” self-draining deck on Formosa’s PRO DECK™ models.

On a Formosa, when the water drains off the deck, the water drains automatically out through two scuppers to the outside of the boat. Other manufacturers can’t do a full self-draining deck, as their floor is too low and below the outer waterline, so the floors are unable to drain to the outside. Instead, the water finds a way into the bilge for the pump to deal with. We’d hate to imagine what happens if the pump fails.

Be aware of these points: If you see an aluminium floor welded to the reverse chine in the bottom sheets of the hull, you have to realise that the structure under the floor is not as high as a Formosa boat. If you see a boat with low sides, it generally means it also has a low floor. If you see an aluminium floor with the only drainage being a bilge pump in a catchment box, this is because the floor is too low to be a true self-draining deck, which is the basis of a true plate boat.

Built for Safety

Every Formosa Marine boat complies with Australian standards and issued with a hull identification number (HIN) which is engraved on the Australian Builders Plate situated on the portside side pocket inside the boat. To meet these standards, there are various requirements, one of which is Buoyancy. Every boat should have a certain amount of flotation installed in the boat, depending on the size and weight of the boat, so as it continues to float when flooded, swamped or capsized.

Formosa Marine boats all have the recommended closed-cell foam fully packed underfloor. Closed-cell foam has excellent buoyancy and low water absorption. Coupled with Formosa’s high floor which not only gives massive strength to the subframe of the boat but also allows for more flotation foam to fit underfloor adding even more safety to your boat.

Questions to ask: Always ask if the boat has foam under the floor. Some manufacturers use air chambers, which if ruptured are rendered useless. If an air chamber is leaking or punctured the air escapes leaving the flotation and your safety on the water compromised.

Water Ballast System

The Formosa Counterbalance

The Quad4™ Water Ballast with Counterbalance has huge advantages over a central water ballast. The stability of a Formosa hull is the best in the business and is accentuated by the Quad4™ Water Ballast feature. Formosa’s Quad4™ Water Ballast has a unique Counterbalance 4 chamber system for extra stability in offshore conditions. By allowing water to enter the hull, Formosa’s Quad4™ Water Ballast minimises hull roll and sway from swell and internal boat movement. Once you’re on your way, the 4 chambers rapidly empty thanks to welded in breathers.

This feature is unique and unlike a more traditional central ballast used by other manufacturers. The Quad4™ ballast is evenly distributed across the hull, so if one side of the boat dips due to internal movement or wave movement, it has to pick up the ballast weight of the other side of the boat, creating a Counterbalance effect. If the ballast is central only, it can allow pivoting at the centre point which means that the boat is stable in the middle but not on the outer extremities of the hull.

Formosa Active Transom Design

The Formosa Difference

Never before has an aluminium boat manufacturer designed a transom which allows the user to access all parts of their boat with ease.

The Active Transom, with 4 design options, offers more versatility and allows the user to utilise the last meter of their boat.

The Step Transom design allows for sitting on the rear pod in comfort or for better access into the boat. The design process allows for flush folding systems which include the transom door and seating, to extend your fishing platform or relax by the water.

It is rare to see an Australian Aluminium boat company invest time, money and energy into value-added designs as Formosa Marine does. Other companies may take the safe and more economic option and follow industry standards. The only person who is Choose from four (4) Active Transom designs to suit you, whether it’s fishing, casting, diving or simply lounging on the back. Take full advantage of the Australian waters by choosing from either the Full Access, Dual Access, Single Access or Closed Access is the consumer, forking out more money for less value.

No other aluminium boat manufacturer can match Formosa Marine’s innovative designs, range of choices and versatility for consumers.

Australian Made

Formosa Marine boats are proudly an Australian owned company building Australian Made products. Every Formosa boat complies with Australian standards of aluminium boat building and is issued with a hull identification number (HIN) which is engraved on the Australian Builders Plate attached to each boat. When you’re looking around for a boat to purchase, ask where the boat manufacturer is based. A lot of boats that are coming from overseas are getting around the rules that are required by companies that build boats in Australia. Safety and comfort are embedded in Formosa Marine’s basic structural boat design and are leaders in innovation, ensuring you can enjoy the Australian waters with a sense of ease. Formosa Marine has you covered.