SAFE BOATING WHEREVER YOU GO

We believe every adventure should be thrilling and safe

Our boats are built to push the boundaries—tested in some of Australia’s most remote and challenging waters to ensure they’re ready for anything. The team at Formosa Marine is committed to constant evolution, always refining our designs to give you the freedom to explore without limits.

Each Formosa boat meets the rigorous Australian standards for aluminium boat construction, as noted on the Australian Builders Plate that accompanies every vessel. We design our boats with your adventures in mind: spacious layouts that minimise trip hazards, ample storage for your gear, superior stability, and true self-draining decks—everything you need to explore the open water with confidence and comfort.

Why is a Formosa so spacious and stable?

Formosa boats are known for their spacious decks, extending all the way to the bow, offering far more usable space compared to other designs. This remarkable space is no coincidence—it’s the result of deliberate and innovative design choices that make every Formosa hull stand out. We’ve fine-tuned our hulls to strike the perfect balance between deadrise, reverse chine, generous freeboard, wide beam, and an ergonomic layout. These features not only make the boat feel larger but also ensure a stable, comfortable experience on the water.

Unlike boats with a sharper deadrise that may feel cramped and less stable during long days on the water, our design provides a generous beam and freeboard for comfort—whether you’re at speed or at rest. Our focus is not just on performance during transit but also on stability and enjoyment when the boat is at rest, creating an environment where you can fully enjoy your time on the water, no matter how many friends or family are aboard.

We invite you to experience the difference for yourself. Compare a Formosa to others on the market, and you’ll quickly see why our spacious decks and stable platform are unmatched—perfect for every adventure.

Unmatched Stability with Quad4™ Water Ballast

Formosa Marine sets a new standard for stability with the innovative Quad4™ Water Ballast system, featuring an industry-leading ‘Off Keel’ counterbalance design. Unlike traditional keel ballasts, the Quad4™ system uses four independent chambers that, combined with our wide beam and reverse chine hull, significantly reduce hull roll from waves and passenger movement. This means you get enhanced stability whether you’re dealing with ocean swells or simply moving about on deck.

When it’s time to power up, the four longitudinal chambers empty quickly, allowing you to get on the plane effortlessly without affecting performance. This advanced feature is available on all Formosa SRT models and sizes.

Even though Formosa boats are inherently stable due to their wide beam and reverse chine design, the Quad4™ Water Ballast system takes stability to another level—especially under offshore conditions. With Quad4™, you get added confidence and comfort for all your on-water adventures, making Formosa boats ideal whether you’re cruising calm bays or venturing offshore.

True Self-Draining Decks

Formosa Marine’s PRO DECK™ is a true self-draining deck system designed to quickly remove excess water from the floor area—whether you’re navigating heavy seas, recovering from a wave, or simply washing down your deck at home. Available as an upgrade on all models from 495 to 595, PRO DECK™ comes standard on all hulls 635 and up (as of March 2023). This advanced deck system is available in a checker plate or carpeted aluminium finish and can also be provided as flat-painted aluminium, ready for EVA marine flooring.

The PRO DECK™ design features large drain channels welded into each corner of the transom, directing water out of the boat through a V-cleat scupper system. This is what makes Formosa’s deck a ‘TRUE’ self-draining solution—since the drainage sits above the waterline, allowing water to exit the boat without requiring a pump. Thanks to Formosa’s high-floor hull design, which sits above the chine line, water can flow out naturally. In contrast, other so-called ‘self-draining’ decks are often welded below the waterline, necessitating bilge pumps to expel water—an unsettling risk if a bilge pump fails.

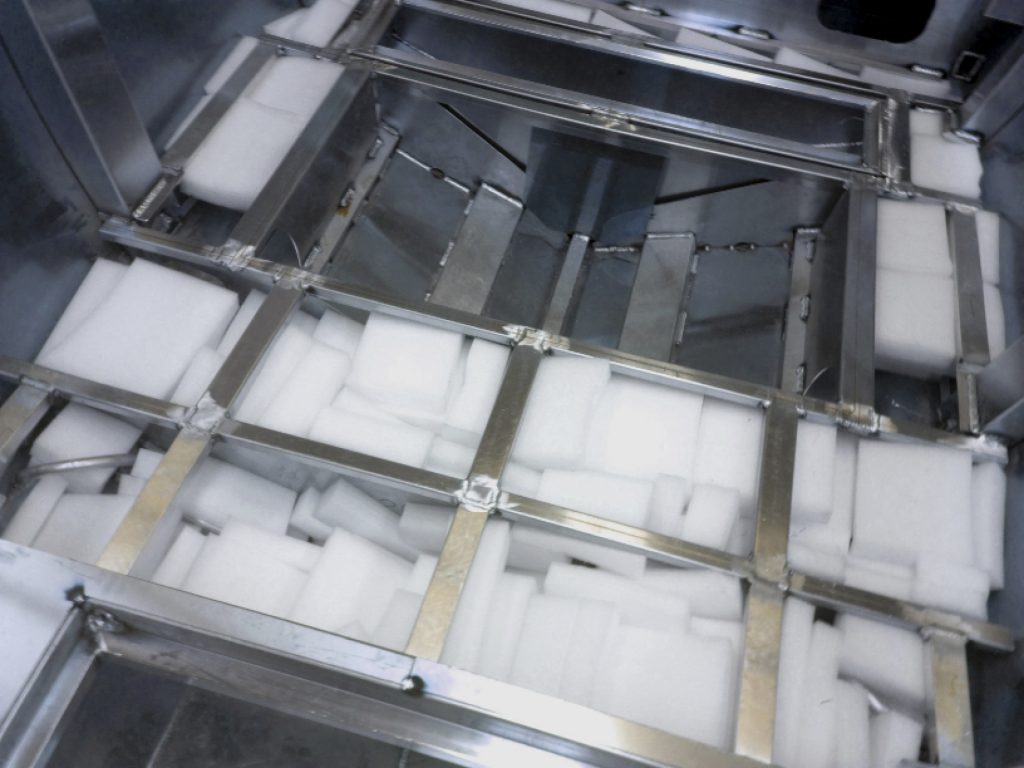

For added peace of mind, every Formosa hull is foam-filled, and an underfloor bilge pump is installed as standard. This ensures that, even in challenging conditions, you have multiple layers of protection and stability built into your vessel.

Built for Safety

Every Formosa Marine boat complies with stringent Australian standards and is assigned a Hull Identification Number (HIN), which is engraved on the Australian Builders Plate situated on the portside side pocket inside the boat. One key requirement to meet these standards is buoyancy. To ensure safety, each boat must include sufficient flotation to keep it afloat if flooded, swamped, or even capsized.

Formosa Marine takes buoyancy seriously by using closed-cell foam, fully packed under the floor of every boat. This foam offers excellent buoyancy with minimal water absorption, providing reliable flotation. Combined with Formosa’s high-floor design—which not only adds massive strength to the boat’s subframe but also creates space for additional flotation foam—our boats provide an exceptional level of safety and security on the water. When you choose Formosa, you’re choosing a boat built with your safety as the priority, designed to handle even the toughest conditions with confidence.

Automatic Bilge Pump

For peace of mind, all boats are fitted with an automatic bilge pump with manual override.

Electrical Harness Kit

Each boat has an electrical harness kit installed with Navigation Lights and Anchor Light.

Under Floor Lock Cell Frame

Gives you structural reinforcement ensuring the main traffic areas are solid underfoot, providing the ultimate stability and a safe environment.

Heavy Duty Hand Rails

Strong 32mm extrusions are fully welded to the gunnels, forward and rear which runs to the floor line on the transom for safe boat access.

Transom Deck Tread

6mm EVA Marine Deck provides a durable, comfortable and safe underfoot surface.

Heavy-duty Bowroller

The aluminium Bowroller is fully welded to the reinforced nose sheet and to the grab rails. Engineered to suit manual deployment and/or drum winches.

Side Pockets

Large side pockets welded to the ribs give extra side strength and plenty of storage.

Tiedown Transom Mounts

To ensure your boat is secure on the trailer, heavy duty tie down mounts are fully welded to either side of the transom.

Aluminium Anchor Well with Winch Mount

The aluminium anchor well features a thick rear mounting plate to support your electric anchor winch — no extra reinforcing is needed.

Moulded Fuel Tank

The underfloor tank is especially moulded to fit into a Formosa hull and positioned central in the boat, under the floor to reduce fuel movement

Battery Isolator Switch

Boats are factory fitted with a two battery isolator switch as standard.

Fuel Breathe

Each tank is fitted with a sender unit and breathers to minimise air blockages.